大倾角带式输送机是指18 ~ 90度的夹角的带式输送机,特殊的通用带式输送机不能带材料,运输会自动下降或空间限制,只能添加挡板皮带运输、大倾角的传播特点,结构紧凑,占地面积少,是一个大倾角输送和垂直提升材料的理想设备,地下开采和地下工程,露天开采,采用大型自卸式船舶机械等领域。

The high angle belt conveyor refers to the belt conveyor with an angle of 18 ~ 90 degrees. The special general belt conveyor can't carry materials, and the transportation will fall automatically or be limited in space. It can only be transported by baffle belt, with the transmission characteristics of high angle. The structure is compact and the floor area is small. It is an ideal equipment for the high angle transportation and vertical lifting of materials. Underground mining and underground engineering, open-pit mining are adopted C-type self unloading ship machinery and other fields.

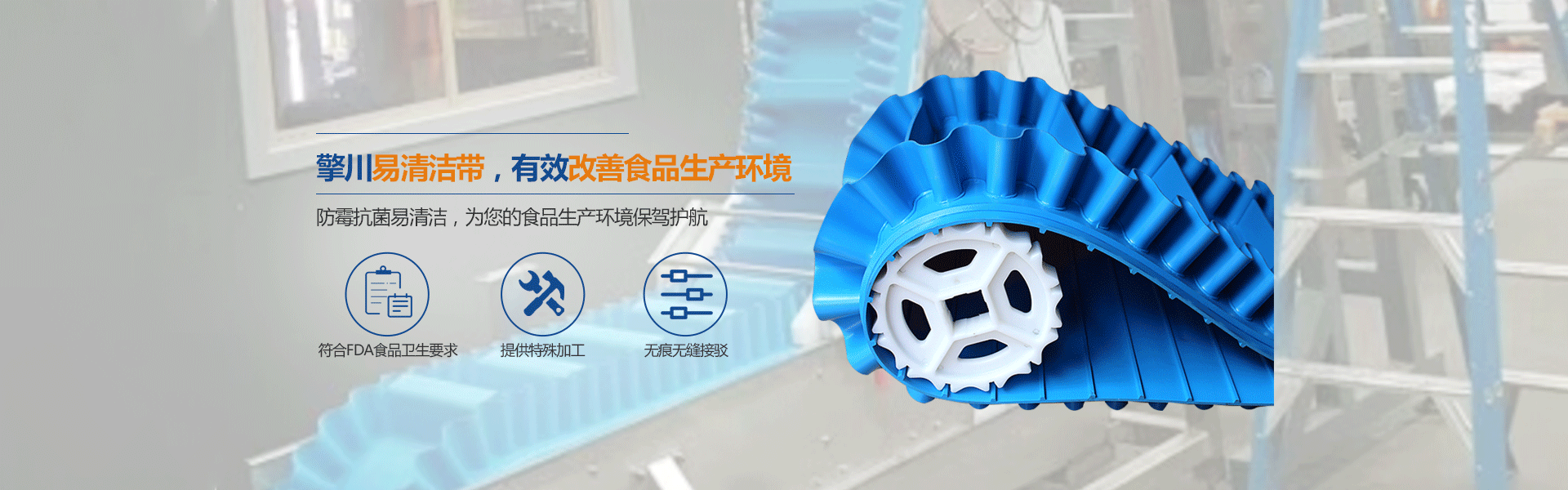

高倾角带式输送机的特点是用波浪型护舷输送带代替普通的输送带。其工作原理和结构与普通带式输送机相同。输送带是基础带,隔板与波浪型挡泥板构成一个整体结构。

The biggest characteristic of high angle belt conveyor is to replace the ordinary belt with wave fender belt. Its working principle and structure are the same as the common belt conveyor. The conveyor belt is the foundation belt, and the clapboard and the wave type fender form an integral structure.

我国大型斜带机的除尘方式多采用集中负压负压袋式除尘。

In China, most of the dedusting methods of large inclined belt machine are concentrated negative pressure bag dedusting.

袋式除尘采用集尘罩、输送管、袋式除尘器、感应风机和烟囱。缺点是投资大;集尘率低;水平管线容易堵塞,影响捕获率。排气量大,运行成本高;除尘器、引风机、烟囱罩面积大;管道复杂,主管径大,支管多,管道长;系统中阀门较多,系统空气平衡调节复杂。需要配备专职运维人员和粉尘输送设备。

Bag type dedusting adopts dust collecting cover, conveying pipe, bag type deduster, induction fan and chimney. The disadvantages are large investment, low dust collection rate, easy blockage of horizontal pipeline, which affects the capture rate. Large exhaust volume, high operation cost; large area of dust remover, induced draft fan and chimney cover; complex pipeline, large main pipe diameter, many branch pipes, long pipeline; many valves in the system, complex air balance regulation of the system. Full time operation and maintenance personnel and dust conveying equipment are required.

目前,大倾角带式除尘的难点在于粉尘的收集和输送。导带槽上设有锥盖,与输送粉尘的管道相连接。为了避免粉尘溢流阀盖,导槽必须处于负压状态;为避免管道内积尘,必须采用大风量输送。这两个因素都需要强大的力量。一旦粉尘沉积,管道内部,排气效率将大大降低,捕集器内的负压状态将被破坏,粉尘将溢出捕集器,捕集器效率将大大降低。采用大倾角袋装除尘技术。运行1 - 2年后,除尘管道堵塞,除尘系统瘫痪,尘点飞扬。另一方面,导槽与波状挡边之间沉积了一定量的物质和粉尘。当皮带进入倾斜角部时,积累的物料和粉尘会从皮带的基带地板上掉落,造成二次粉尘污染。

At present, the most difficult point of large angle belt type dust removal lies in the collection and transportation of dust. The guide belt groove is provided with a cone cover, which is connected with the pipeline for conveying dust. In order to avoid the dust overflow valve cover, the guide groove must be in the negative pressure state; in order to avoid the dust accumulation in the pipeline, large air volume must be used for conveying. Both of these factors need strong power. Once the dust is deposited in the pipeline, the exhaust efficiency will be greatly reduced, the negative pressure state in the catcher will be destroyed, the dust will overflow the catcher, and the efficiency of the catcher will be greatly reduced. The dust removal technology of big angle bag is adopted. After 1-2 years of operation, the dedusting pipeline is blocked, the dedusting system is paralyzed, and the dust point is flying. On the other hand, a certain amount of material and dust are deposited between the guide groove and the corrugated edge. When the belt enters the inclined corner, the accumulated materials and dust will fall from the baseband floor of the belt, causing secondary dust pollution.